VBD Double Seat Butterfly Valve

VBD series butterfly valve is a type of flow control device, used to make a fluid start or stop flowing through a section of pipe. It is well applied to stainless steel pipe systems for food, beverage, dairy, brewing, pharmaceuatical, bio-pharmaceuatical and chemical industries.

• Operation: Manual, Pneumatic, Electric

• Body Materials: AISI-304 or AISI-316L

• Gasket Material: Silicon, EPDM, VITON, NBR

• Size Available: 1/2"-10" or DN15-DN250

Application

VBD series butterfly valve is a type of flow control device, used to make a fluid start or stop flowing through a section of pipe. It is well applied to stainless steel pipe systems for food, beverage, dairy, brewing, pharmaceuatical, bio-pharmaceuatical and chemical industries.

Materials

- Body Materials: AISI-304 or AISI-316L

- Gasket Material:Silicon, EPDM, VITON, NBR

Valve seat and gasket comply with FDA 21CFR177.2600

Standard Design

- Standard Avaliable: DIN, SMS, ISO / IDF, BS / RJT, and ASME / BPE.

- Available in sizes from DN15 / 1/2" to DN250 / 10"

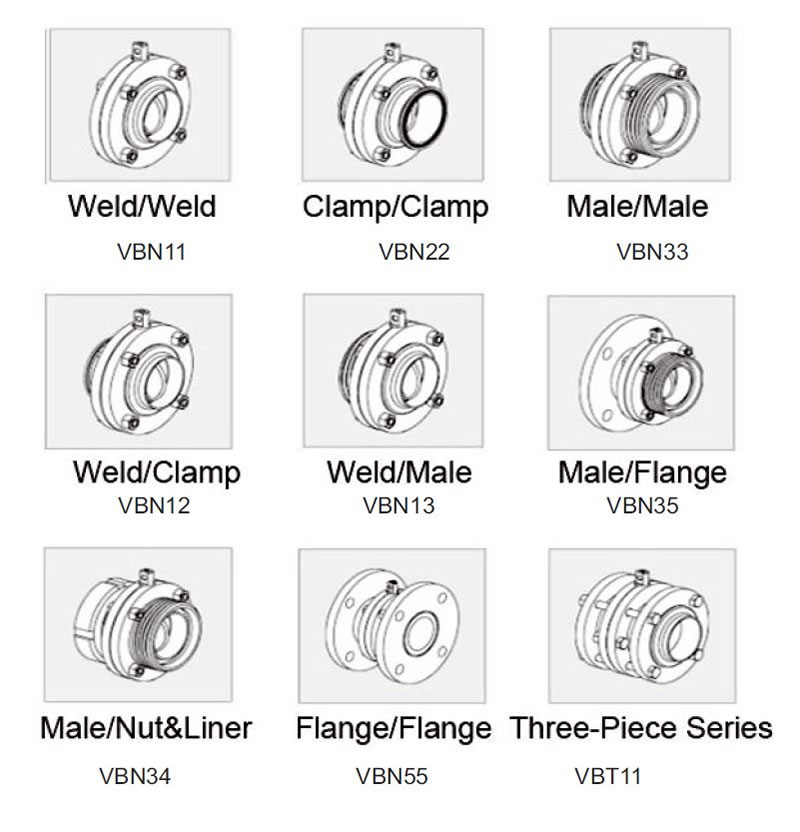

- End connection: Butt-weld, Clamp, Male, Nut, Liner or Flange or others upon request.

- Handle: plastic pull handle (2-4 positions) or plastic/stainless steel squezee handle (13 positions)

- Actuator: pneumatic stainless steel actuator (vertical type), pneumatic aluminum actuator (horizontal type), electric actuator.

- Control: position sensor, C-top controller, C-top controller (AS-I)

- Manual handle, pneumatic actuator and electric actuator are interchangeable.

Technical Specification

- Max. pressure: 10bar (145psi) DN25 ~ 100; 8bar (120psi) DN125 ~ 150

- Temperature range: 14 ~ 248°F (-10 ~ 120°C), EPDM

- Surface treatment: Ra 16 ~ 32µin (0.4 ~ 0.8µm)

- Supply pressure for air actuator: 70 ~ 115psi

Connection Type

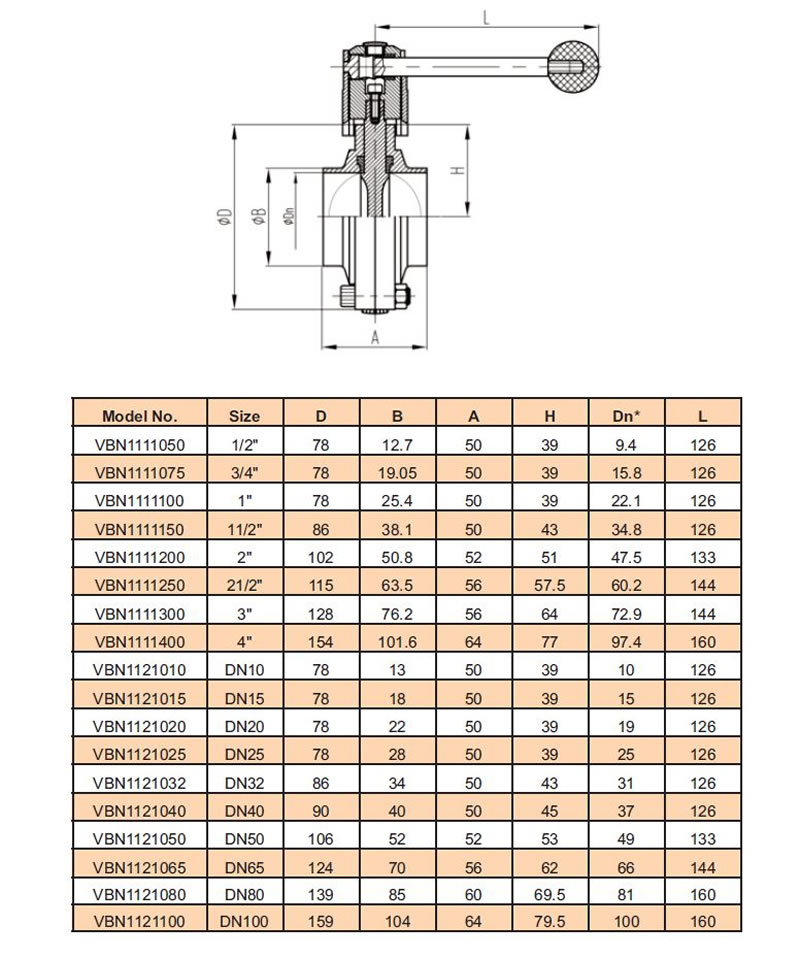

Technical Parameters

Technical Parameters |

|||

| Steel material | Product wetted steel parts | AISI 316L / 304 forged (1.4306 / 1.4404) |

Provided with material inspection report |

| Other steel parts | AISI 304 | ||

| Seal material | Standard | EPDM | All seal materials comply with FDA 21CFR117.2600 |

| Options | VMQ / FPM | ||

| Pressure | Working pressure | ≤10bar (145psi) | |

| Supply pressure for air actuator | 5 ~ 8bar (70 ~ 116psi) | ||

| Temperature | Working temperature | EPDM: 14 ~ 248°F (-10 ~ 120°C) VMQ: -58 ~ 356°F (-50 ~ +180°C) FPM: -22 ~ 446°F (-30 ~ +230°C) Other materials are available upon request |

|

| Sterilization temperature | 302°F (150°C, Max. 20 min) | ||

| Surface treatment | Inside surface treatment | Ra 16 ~ 32µin (0.4 ~ 0.8µm) | |

| Outside surface treatment | Ra32 ~ 64µin (0.8 ~ 1.6µm) | ||

| Connection | The welding diameter | Welding ends: DIN 11850-2 with 11850-1 / SMS / 3A / ISO Series, etc. |

|

| End connections: butt-welded, sanitary clamp, male and female threaded, flanged, I-line or others upon request. | |||

Drawing